Tuesday, 9 March 2021

Anchoring Contractors Cochin,kerala provides high quality technicians

Monday, 8 March 2021

Epoxy Coating – Build Care Waterproofing Solutions

Epoxy coating

Build

Care is a popular epoxy coating contractors in Kochi, Ernakulam and Kerala. With a rich experience in the respective field

of work, Build care provides valuable Epoxy Coating services, which meet the

requirements of our clients. Our services are widely accepted since this help

to keep the work station clean from concrete dusting, protect the

substrate from chemical and physical degradation and reduce the maintenance

expenses and cleaning

costs. Our team of professionals works in close co-operation

with each other to render all services effectively and in a timely manner.

We provide a wide range of Epoxy Flooring & Coating services, with the guidance of our dedicated professionals. Our Epoxy coating services are used by various reputed organizations to provide a clean and gentle look to their work places, residential areas and shopping malls.

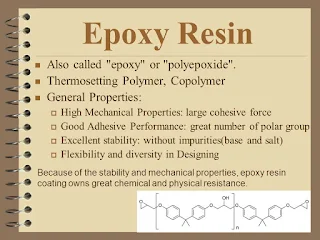

What Is Epoxy Coating?

Epoxy coating is the most durable

finishing of your floor. This not only provides a clean and

gentle look for your floor. It is resistant to

stains and water.

Epoxy is an actual thermosetting

resin used as a coating. Thermosetting resin is a prepolymer in a soft solid or viscus state. When

you mix one part of epoxide resin with one part of polyamine hardener, curing

process will occur. The curing process

is induced by heat or

radiation under high

pressures. Products of this curing process provide the strength

and durability for epoxy. Formation of a coating is the end result of these

reactions. It is Epoxy Coating.

Advantages of our Epoxy Flooring & Coating services:

- Provides

cleaner, healthier, more pleasant work station

- Protects

concrete structures from wear and patch, making it last longer and durable

- Prevents

concrete dusting

- Protects

the substrate from chemical and physical degradation

- Cuts

down on amount of lighting needed in plant

- Makes

the plant appealing well

- Helps

to keep finished parts clean before shipping

- Cuts down maintenance and cleaning costs

Colors and themes

We

provide different types of colors and patterns. The customer can select the

theme as they like or that are good to the store.

We

offer a wide range of Epoxy Flooring & Coating services, with the guidance

of our dedicated professionals. Build Care is the best epoxy coating

contractors in Kochi, providing better and quick services for you.

Monday, 11 January 2021

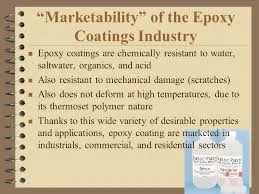

Advantages of using Epoxy Floor Coating - Buildcare waterproofing

- Durable and easy to clean

- Resists oil stains and water

- Can be combined with paints and colours to mask off chips and cracks

- Creates a shiny high-gloss surface that can significantly increase the brightness of interior area

- Prevents wear and tear on existing concrete floors

- Offers a hard-wearing durable surface able to withstand heavy and continuous traffic

- Creates a seamless surface that can last many years

- Requires little or no major maintenance

- Ideal for warehouses and industrial applications

- Quick and easy to install, requiring no layout, cutting additional adhesives, or special tools or equipment

- Offers enhanced safety when the surface contains anti-slip additives

- Can be applied in different patterns to create visible driveways and/or identify walkable areas

- Provides a chemically resistant surface ideal for manufacturing plants.Epoxy also known as polyepoxite is produced by the bonding of two compounds, the epoxide which is the resin and polyamine which is the hardener. The result of the mixture is a tough sealant that is resistive to chemical absorption. Epoxy flooring may be generally defined as several layers of any type of epoxy resin that is applied on a floor surface. The applied epoxy on the flooring should have a minimum of 2mm in thickness. Other uses of epoxy are in industrial tooling, electrical systems, marine application and aerospace industry.Hope you have got a brief idea on Epoxy floor coating. You can post the comments for more queries.Jemy Joseph.

Sunday, 20 December 2020

Importance of Expansion Joints in Architectural Structures

Importance of Expansion Joints in Architectural Structures

Expansion joints

Expansion joints is an assembly, that designed to hold parts together. It safely absorb the expansion and contraction of construction materials affected by heat.They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Building faces, concrete slabs, and pipelines expand and contract due to warming and cooling from seasonal variation, or due to other heat sources. Before expansion joint gaps were built into these structures, they would crack under the stress induced. It can act as more than one joint at a time. Since it can move it is also known as a movement joint. Along with controlling the expansion and contraction, movement joints can prevent the cracking of floor and cement structure.

Expansion joints are used in piping systems to absorb thermal expansion or terminal movement where the use of expansion loops is undesirable or impractical. Expansion joints are available in many different shapes and materials.Applications of Expansion joint

- Vibration, Noise, Shock, Corrosion, Abrasion

- Stresses, Load Stress, Equipment Movement

- Vibration, Pressure Pulsation and Movement in a Piping System

- internal or external pressure at working temperature

- weight of the pipe it self and the parts supported on it

- movement imposed on pipe sections by external restraints

- thermal expansion

Tuesday, 20 October 2020

Anchoring Contractors Cochin,kerala provides high quality technicians

Anchoring Contractors Cochin

BuildCare is a leading Anchoring Contractor and expert epoxy system specialist in Kerala with highly efficient and dedicated technicians. The expert engineers check the groundwater level of the building and decide what kind of waterproofing method is needed.

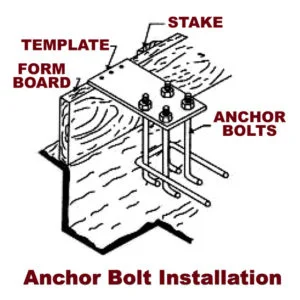

What is Anchoring?

The Build Care waterproofing provides best Anchoring Contractors in Cochin with high-quality technicians and installs anchoring system of rock bolts, rock anchors tiebacks, tie-downs, earth anchors, soil nails, concrete anchors and post-tension tendons in buildings. The durability, sturdiness and strength of steel make it a perfect choice for anchoring systems. It is made high strength steel bars or strands. It is long-lasting, reliable, and economical tension supports are used to stabilize and secure buildings.

Anchoring systems can be bonded to rock, concrete and different terrain surfaces. They are used to resist external overturning uplift and seismic forces and are used actively and passively in buildings.

How anchoring is done

The soil and rock nails are fully grouted and passive anchors are used for resisting the uplift forces and failure forces on slopes or excavation. The nails take advantage of residual stress in the soil or rock for load transfer. Passive anchors are normally used where prestressing is either not possible or desirable. Rock and concrete anchors are prestressed with tendons which can be bars or multiple strands. A portion of the length is bonded to rock using concrete by cement grout, resin or fixed using a mechanical anchor. The upper portion is left ungrouted for prestressing. However, it is later grouted to lock in tension and protect from corrosion.

Wednesday, 14 October 2020

Terrace Waterproofing For Garden Making - Buildcare Waterproofing

What is the need?

Gardening is fun and therapy for some. But when you are living in an urban environment and you do not have enough space to make your garden, what do you do? You take it up to the only place you can make it happen. The roof. But if you make your garden up on the roof without proper preparation it will cause more damage than you imagine. The biggest threat is the roots of the plants penetrating the roof. This will cause water leakage. It will cause significant damage to the roof and in turn the whole structure. So it is necessary to make preparations to protect the roof before gardening. Terrace Waterproofing For Garden Making is the solution here. There are many methods of waterproofing and all are easy to do. A waterproofing polymer is used for this purpose. Once it is done you can plant your garden without any concern and enjoy the blooms.

How it is done

The waterproofing is done by applying different layers of coating with each of them having its own purpose as shown above. The whole coating consists of a waterproof membrane which comes directly on top of the roof. A flexible membrane is used for easy movement. And a physical barrier for the roots is applied. Sometimes a UV resistant barrier is also used.

To put it simply waterproofing the roofing is quite beneficial. Doing this during the construction process itself will help ensure longlasting life for the building.

Tuesday, 6 October 2020

Importance of Expansion Joints in Architectural Structures

Expansion Joints in Architectural Structures

Expansion Joints

Importance of Expansion Joints in Architectural Structures

Types of Expansion Joints

- Bridge Expansion joints

- Railway Expansion Joints

- Ducted Air Systems

- Pipe Expansion Joints

- Rubber Expansion Joints

- Fabric Expansion Joints

- Metal Expansion Joints

Expansion Joint Accessories

- Liners

- Covers

- Particulate Barriers

- Limit Rods